Video

1 / 6

Wholesale Prices Cosmetic machine production line /cosmetic cream mixer/vacuum homogeneous emulsifying machine

$4500.00

~ $20000.00

/ Set/Sets

Options:

- 300L vacuum mixing emulsifier

envoyer une demande

| Mixer Type : | Agitator |

|---|

plus

2yrs

Wenzhou, Zhejiang, China

- Fabricant

- Service OEM

- Fournisseur or

- Certification de plate-forme

Wenzhou Zoncic Machinery Technology Co.,Ltd

Description du produit

Product Description

Purpose: The equipment is suitable for emulsification of the pharmaceutical. Cosmetic, fine chemical products, especially the material having high matrix viscosity and solid content. Such as cosmetic, cream, ointment, detergent, salad, sauce,lotion, shampoo, toothpaste and so on

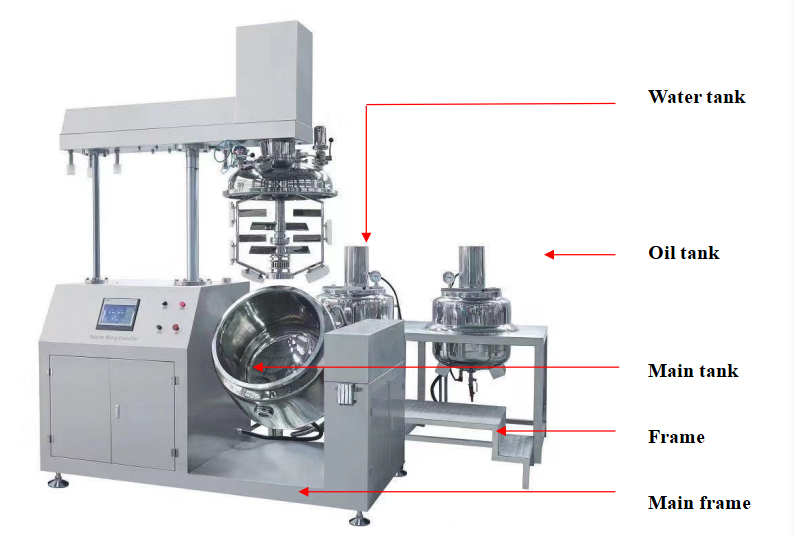

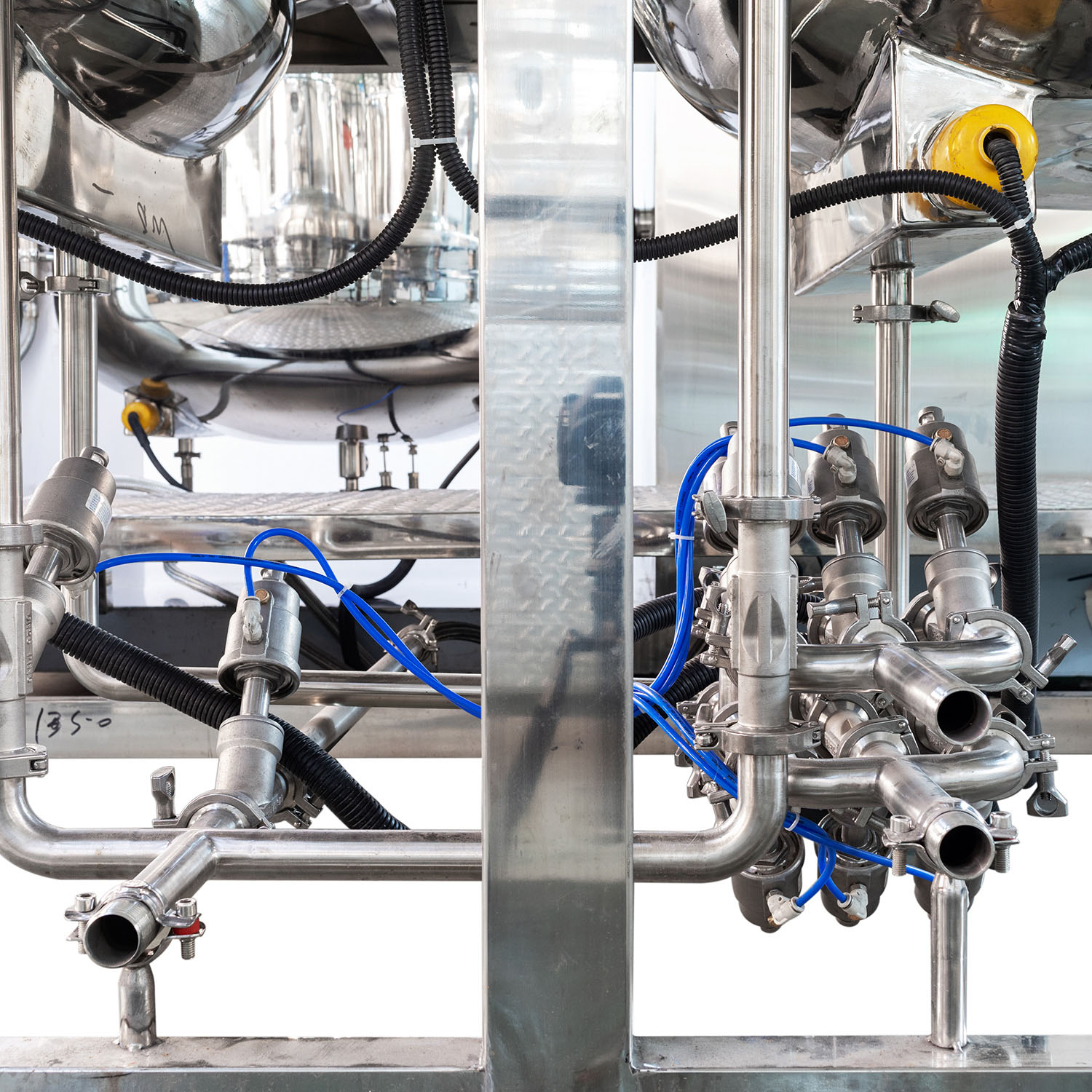

Structure:including main emulsifying pot, water pot ,oil pot and work frame。

1 Usually the oil pot is used for dissolving some solid that the product can just only be dissolved into oil, then the dissolved solvent will be sucked into the emulsify pot by soft pipes.

2 The function of water pot is the same to the oil pot.

3 emulsify pot is used for emulsifying the products that suck from the oil pot and water pot.

Main frame: including emulsify pot, lifting system, discharge system, vacuum system, electric control system, rotate system, mixing system.

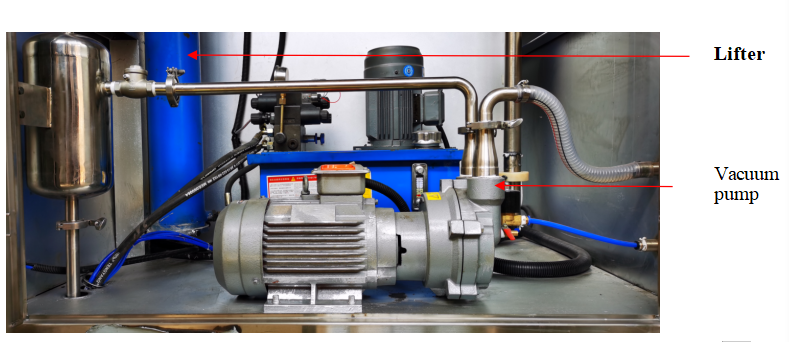

Vacuum pump is connected by two soft pipes, one is connected the water tank by soft pipe which is used for sealing when the pump is operating; the other connected to main emulsify pot through pipes and gas—liquid separator, so that the pump can make the main emulsify pot under vacuum condition. The gas—liquid separator is separating the gas and water, because the steam is sucked into vacuum pump when it is working, the steam through gas---water separator, some of steam become into water which flow out at the bottom of the separator.

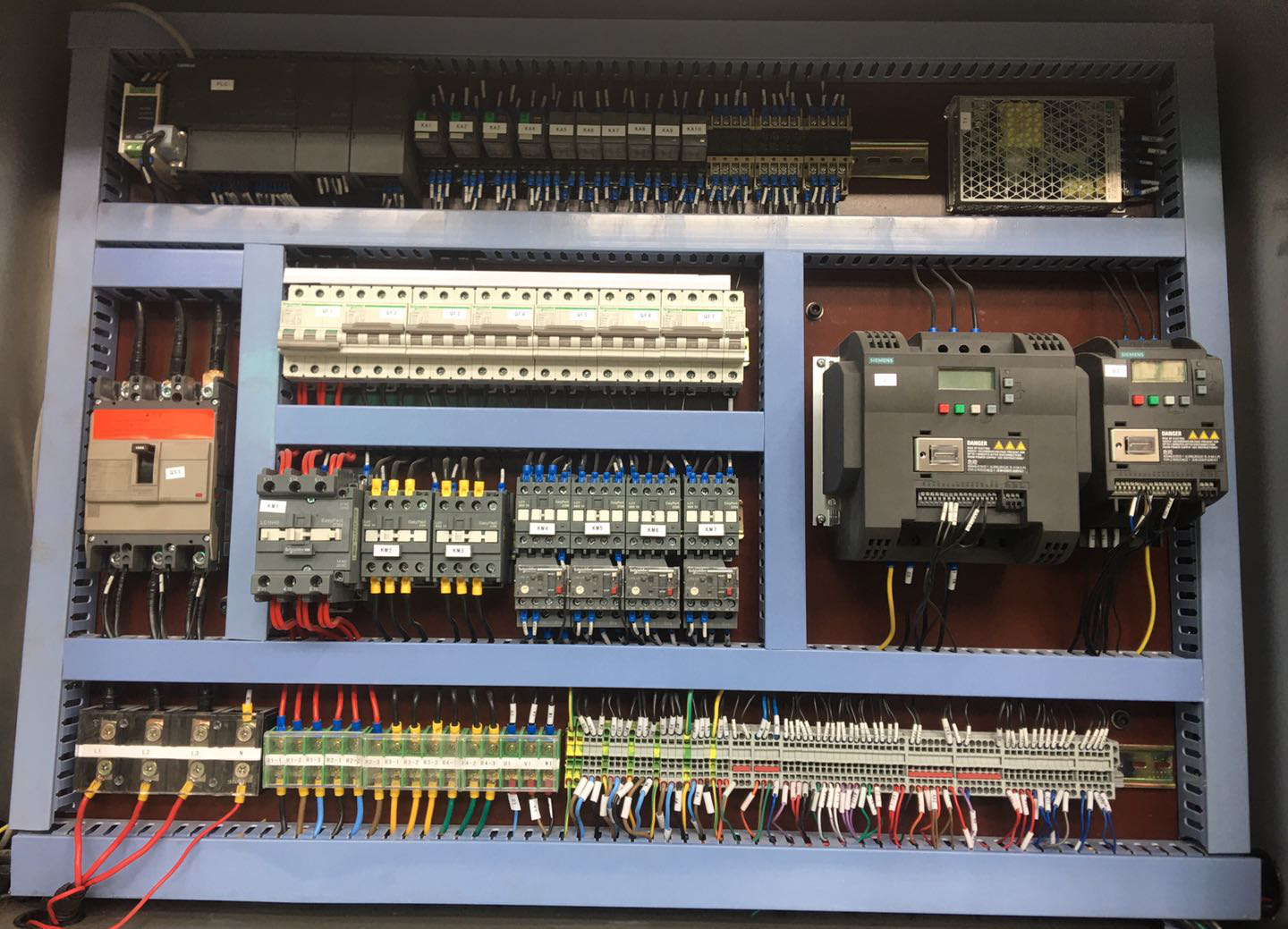

Electric control system

The vertical motor is high speed motor which can rotate between 0—3500 rmp/min

You can demolition the motor by open the screws and one wire.

Mixer: it include low speed mixer and high speedy mixer (homogenizer)

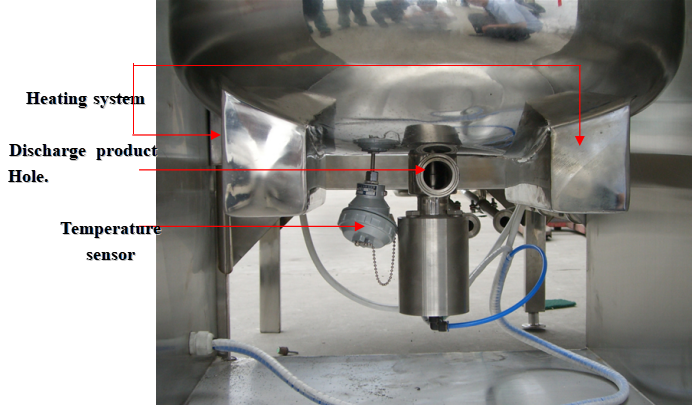

a)Emulsifying pot:including cover, pot, bottom valve, temperature sensor, heating system.

This machine is heated by electricity, you just fill water into jacket, then turn on the heating system, the water is heated by electricity according to your requirement.

2 this machine also can be heated by steam, you just connect to steam producer when you heat the machine by steam.

Discharge hole: it is used for discharging the product just open the valve by pressed air.

Temperature sensor: it is used for check the temperature the product inside pot

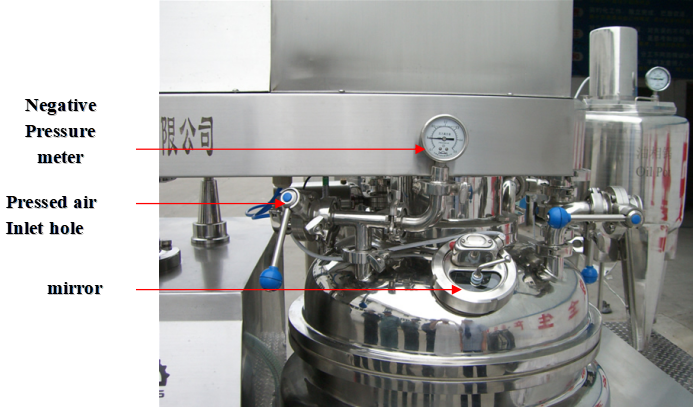

Accessories on the cover: including vacuum protection system, pressed air inlet hole, negative and plus pressure meter, mirror, CIP that for washing, break vacuum hole, material inlet hole, prepare hole for inlet perfume, automatic control vacuum valve and so on.

Break vacuum hole: it can break the vacuum inside pot by turning the valve, there is air filter inside valve. The product can not be discharged under vacuum condition, it just can be discharged without vacuum.

CIP: it is used for cleaning the inside pot by connecting tap water

Perfume inlet: it is prepare hole for put perfume into the pot.

Suck product inlet pipe: it is used for sucking product from the oil pot and water pot.

You also can suck the product from oil pot and water pot to emulsify pot by vacuum through the stainless steel pipe.

This vacuum protection switch is designed so that the cover can not be lifted when it is vacuum inside pot.

Vacuum protection switch

Safety system:

Water inlet system and cooling system

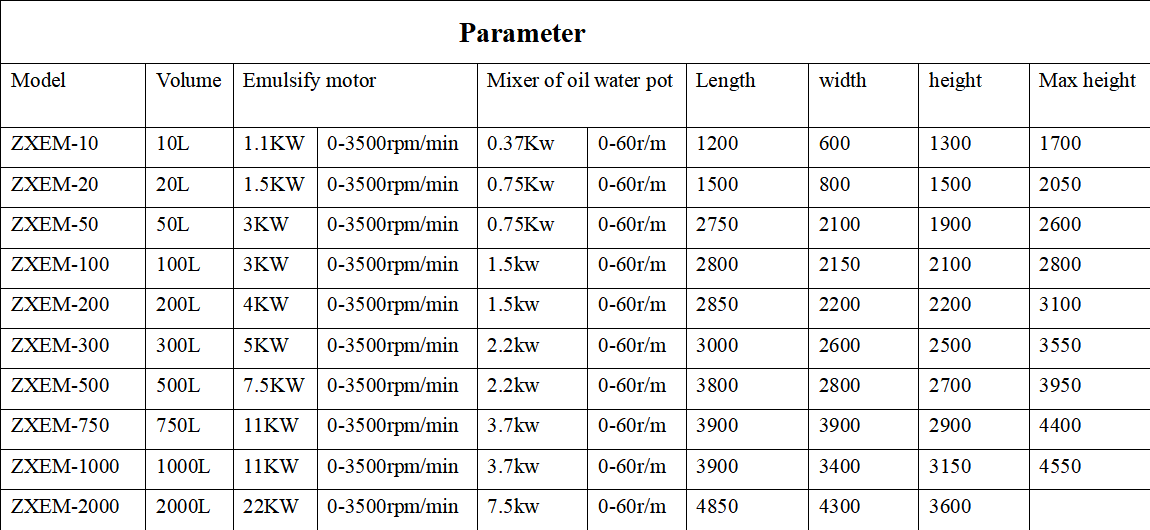

Specification

Category name | 300L vacuum mixing emulsifier |

Spindle speed range | 0-3500 rmp/min |

Electric components

Production Room

INSTALL PICTURE:

Packing & Delivery

Company Profile

Wenzhou Zoncic Machinery Technology Co., Ltd. was established in 2014, formerly known as Haibin Chemical Machinery Factory, with a history of more than 20 years. It is a high-tech enterprise specializing in the research and development, manufacture and sales of equipment in the pharmaceutical, chemical, food, biological and other industries. It mainly produces CBD extraction, molecular distillation, vacuum drying equipment, fermentation tanks, emulsifiers, granulators, paging machines, packaging machines,etc. Zoncic Machinery has an experienced team of engineers who can conduct technical exchanges with customers in a timely and effective manner and offer the best solution; Zoncic Machinery has a skilled production team that can complete equipment production and inspection on time and guarantee product quality; Zoncic Machinery has a passionate sales team that can maintain close communication with customers 24 hours online to meet customer needs; Zoncic Machinery has a hard-working ins tallation team that can actively cooperate with customer needs to install and debug equipment on site to ensure equipment operation; Zoncic Machinery has a patient and responsible after-sales team that can deal with customer feedback and solve customer doubts in the first time. Our equipment is exported to Southeast Asia, Europe, the United States and other regions and has been unanimously praised by customers. Our aim is to make our equipment worthy of praise.

FAQ

1 .Q Do you accept a customized order?

A: Yes ,we do ; We could manufacture all kinds of required equipments according to your technical drawings;

2.Q: Can you make a design for us?

A:Yes, we could making a production line according to customer’s requirements. We could do the key project. 3.Q:Can your engineer come to our place for installation guides?

A:Yes, we could. We will provide a video and document for installation;If you still have problems we will send our engineer oversea for installation guide;

4.Q:When is the lead time? A: In 50 days after receiving the deposit. For your inquiries, pls kindly let us know:

1. What is your products? Cream,toothpast, moisturizer,night cream, vanishing cream,suncream etc.

2. What is the capacity do you want for this vacuum emulsifying machine? 100L,200L300L,500L,1000L, etc.

3. Required heating method: electric heating or steam heating?

4. Required voltage and frequency of power supply? eg:380V 50Hz 3phase?

5. Requirement of Certificate

Video

2yrs

Wenzhou, Zhejiang, China

- Fabricant

- Service OEM

- Fournisseur or

- Certification de plate-forme

Envoyez votre demande à ce fournisseur

envoyer une demande