1 / 3

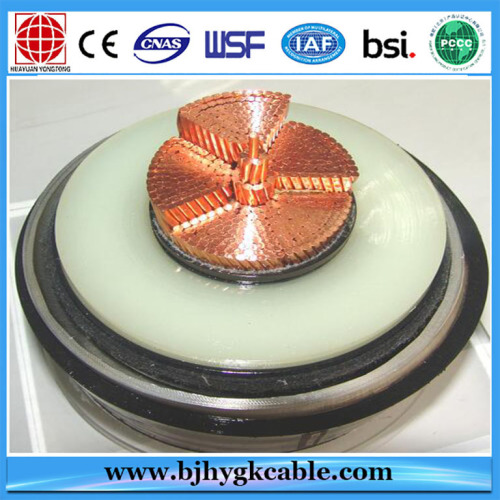

Câble d'alimentation blindé en alliage de plomb isolé 230 kV XLPE

| Model No. : | YJQ03 |

|---|---|

| Brand Name : | HUAYUAN YONGTONG |

| Application : | Construction |

Beijing, Beijing, China

- Distributeur grossiste

- Fabricant

- Service OEM

- Certification de plate-forme

- Vidéo

Description du produit

Beijing Huayuan Gaoke Cable Co., Ltd a été créé en 1998, situé dans le district de Daxing à Beijing en Chine. L'usine couvre une superficie de plus de 20.000 mètres carrés et a dix-huit équipements de production avancés nationaux et étrangers de câbles d'alimentation jusqu'à 110kv câbles isolés par XLPE. Société a introduit avec succès des lignes de production de câbles en alliage d'aluminium, ligne de production de câbles résistant au feu isolées minérales et ligne de production de câbles en caoutchouc de silicone en 2012. La société vise à rechercher qualité parfaite, innovation technologique, efficacité énergétique et protection de l'environnement. Huayuan est devenu une étoile montante dans les entreprises high-tech chinoises du câble. Les entreprises ont adopté la certification ISO9001: 2008 système de gestion de la qualité, certification GB / T28001-2011 de santé et de sécurité au travail, ISO14001: 2004 certification de gestion environnementale, certification CCC, le permis de production industrielle nationale, fournisseurs qualifiés de bureau d'alimentation électrique à Beijing sur, le câble isolant de feu resitent le BSI CERTIFICATE comme BS 6387: 2013, tous les produits rencontrent les normes nationales de fil et de câble. nos câbles avaient été exportés vers l'Asie du sud-est, l'Europe, Amérique du Nord, Amérique du Sud pour beaucoup de projets principaux.

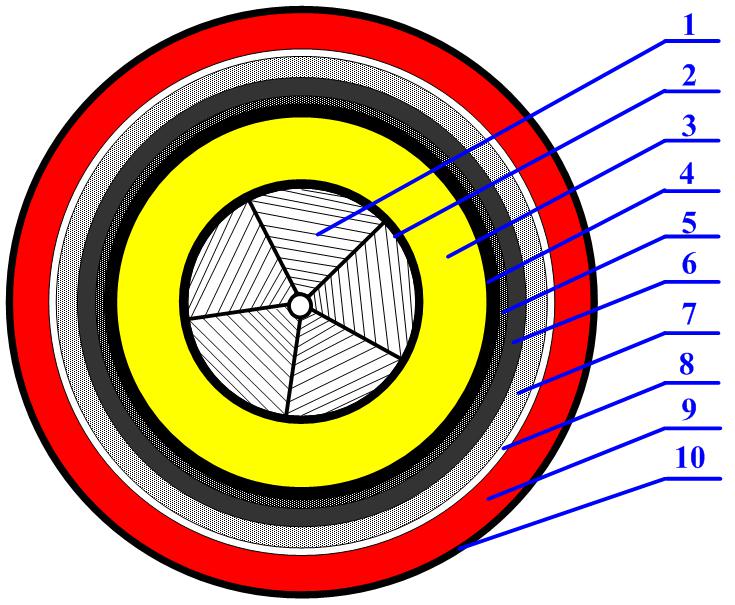

Construction

CU / XLPE / LAS / PEHD 130 / 230kV 1 * 2500 mm2

|

Basic Structure |

Nominal Thickness mm |

Nominal Outer Diameter mm |

|

1. Water blocking five(5) Milliken (segmental) copper conductor |

/ |

61.0±1.0 |

|

2.Semi-conductive tape |

0.14 |

62.0 |

|

3.Conductor screen (wrapping + extruding) |

2.5 |

66.0 |

|

4.XLPE insulation |

25.0 |

116.0(-1.5,+1.0) |

|

5.Insulation screen |

1.5 |

119.0 |

|

6.Semi-conductive water blocking tape |

2.0 |

121.0 |

|

7.Lead alloy E sheath |

4.0 |

129.0 |

|

8.Anti-corrosive layer (bitumen) |

0.25 |

129.5 |

|

9.HDPE Outer sheath |

5.0 |

139.5 |

|

10.Semi-conductive layer (coating) |

|

139.5±3.0 |

spécification

CÂBLE D'ALIMENTATION (CÂBLES À HAUTE TENSION)

|

NOMINAL VOLTAGE KV DESCRIPTION Particular |

UNIT |

REQUIRED 230kV 1x2500 |

OFFERED |

|

|

1 |

Maker`s Name |

|

Beijing Huyan Gaoke CABLE |

Beijing Huayuan |

|

2 |

Standard specifications applying to |

|

IEC STANDARD |

|

|

2.a |

Cable |

|

IEC 62067 & IEC 60811& IEC 60229 |

IEC 62067 & IEC 60811& IEC 60229 |

|

2.b |

Copper |

|

IEC 60228 |

IEC 60228 |

|

2.c |

Cross linked polyethylene |

|

IEC 62067 & IEC 60811 |

IEC 62067 & IEC 60811 |

|

2.d |

Protective covers |

|

IEC 62067 & IEC 60229 |

IEC 62067 & IEC 60229 |

|

3 |

Type of cable |

|

Cu/XLPE/LEAD/HDPE |

Cu/XLPE/LEAD/HDPE |

|

4 |

Rated voltage |

kv |

130/230 |

130/230 |

|

5 |

Max. continuous operating voltage |

Kv |

245 |

245 |

|

6 |

Max. field strength at nominal voltage |

Kv/mm |

4 at insulation surface 6.94 at inner insulation surface |

3.94 at insulation surface; 6.99 at inner insulation surface |

|

7 |

Number of cores/cable |

|

Single cores |

Single cores |

|

8 |

Form of conductor |

|

Milliken Stranded copper Conductor With Swelling Powder |

Milliken Stranded copper Conductor With water blocking tape |

|

9 |

Nominal cross section/core |

mm2 |

2500 |

2500 |

|

10 |

Number and diameter of strands/core |

mm |

5 Segmental X61 wires X 3.5 mm wire diameter |

5 Segmental ×91 wires × 2.76 mm nominal wire diameter |

|

11 |

Thickness of layers between conductor and outer jacket |

|

|

|

|

11.a |

Semi-conductor Smoothing tape over conductor with 30 % over lap and the thickness is (0.15) Nominal Minimum |

|

0.15 0.1

|

Semi-conductor water blocking tape over conductor with 20 % over lap and the thickness is 0.3 0.2 |

|

11.b |

Semi-conductor water blocking tape over SCT (item 11 .a) with 30 % over lap and the thickness is (0.2) Nominal Minimum |

|

0.2 0.18 |

Semi-conductor tape over SCTWBT

0.14 0.1 |

|

11.c |

Extruded Semi-conductor layer over SCWBT(item 11.b) Nominal Minimum |

mm |

1.5

1.3 |

Extruded Semi-conductor layer over SCT 2.2 1.2 |

|

11.d |

Insulation Nominal Minimum |

mm |

25 22.5 |

25.0 22.5 |

|

11.e |

Extruded Semi-conducting layer over insulation Nominal Minimum |

mm |

1.5

1.3 |

1.5 1.2 |

|

11.f |

Separator layer before lead sheath with 30 % over lap and the thickness is (2) Nominal Minimum |

mm |

2 1.8 |

Tow layer 30% Gap 2.0 1.5 |

|

11.g |

Method of conductor tightness |

|

1- swelling powder inside conductor layers 2- swelling tape between segmental 3- swelling tape over conductor 4- swelling tape over outer semi-conductive |

1- water blocking rope core 2- water blocking tape between segmental 3- water blocking tape over conductor |

|

12 |

Thickness of lead sheath Nominal Minimum Total C.S.A |

mm mm mm2

|

4 3.7 1675 |

4.0 3.7 1570(calculated value) |

|

13.a |

Material & thickness of outer protective anti-corrosion layer Nominal Minimum |

mm |

HDPE 5 3.8

|

HDPE 5.0 3.8 |

|

13.b |

semi-conductive extruded layer or graphite coating Nominal |

mm |

Semi-conductive graphite coating 0.05 |

Semi-conductive graphite coating 0.05 |

|

14 |

Nominal overall diameter of cable Nominal(approximate) |

mm |

147 |

139.5 |

|

15 |

Weight of cable/1000m |

|

|

49650 kg(approx.) |

|

15.a |

Copper (Conductor) |

Kg/km |

22500 ± 1% |

22500± 1% |

|

15.b |

lead |

Kg/km |

18950 |

18770(approx.) |

|

15.c |

Total weight of cable |

Kg/km |

52110 |

49650 kg(approx.) |

|

16 |

Length of cable supplied on each drum |

M |

500 (-0 + 5%)

|

500 (-0 + 5%)

|

|

17.a |

Net weight of loaded drum(Approximate) |

Kg |

26055 |

24825 |

|

17.b |

Gross weight of loaded drum(Approximate) |

Kg |

28055 |

27625 |

|

18 |

Dimension of drum |

|

|

|

|

18.a |

Diameter |

m |

4.0 (Steel) |

4.0 (Steel) |

|

18.b |

Width |

m |

2.2 |

3.2 |

|

19 |

Method of laying and pulling erection |

|

By mean of pulling eye attached to the conductor |

By mean of pulling eye attached to the conductor |

|

20 |

Min. bending radius |

|

|

|

|

20.a |

In soil |

mm |

4410 |

3490 |

|

20.b |

In duct |

mm |

5145 |

3490 |

|

20.c |

Placed in position: Without former With former |

mm mm |

2940 2205 |

2790 2790 |

|

21 |

Max. Safe pull on cable during installation. |

Kg |

15000 on pulling eye |

15000 on pulling eye |

|

22 |

Summary of tests standards at works as specified |

|

|

|

|

22.a |

Routine test |

|

IEC 62067& EETC Specification |

IEC 62067& EETC Specification |

|

22.b |

Sample test |

|

IEC 62067& EETC Specification |

IEC 62067& EETC Specification |

|

22.c |

Type test |

|

IEC 62067& EETC Specification |

IEC 62067& EETC Specification |

Usine et équipement

Beijing, Beijing, China

- Distributeur grossiste

- Fabricant

- Service OEM

- Certification de plate-forme

- Vidéo

Envoyez votre demande à ce fournisseur